Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

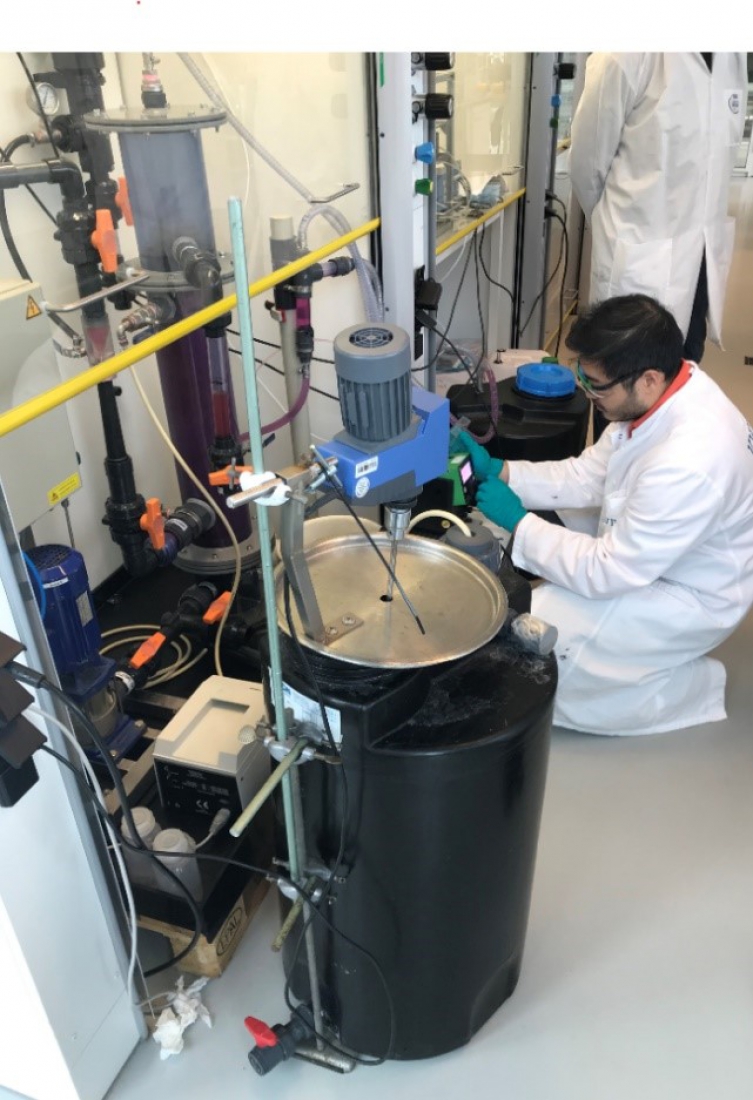

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

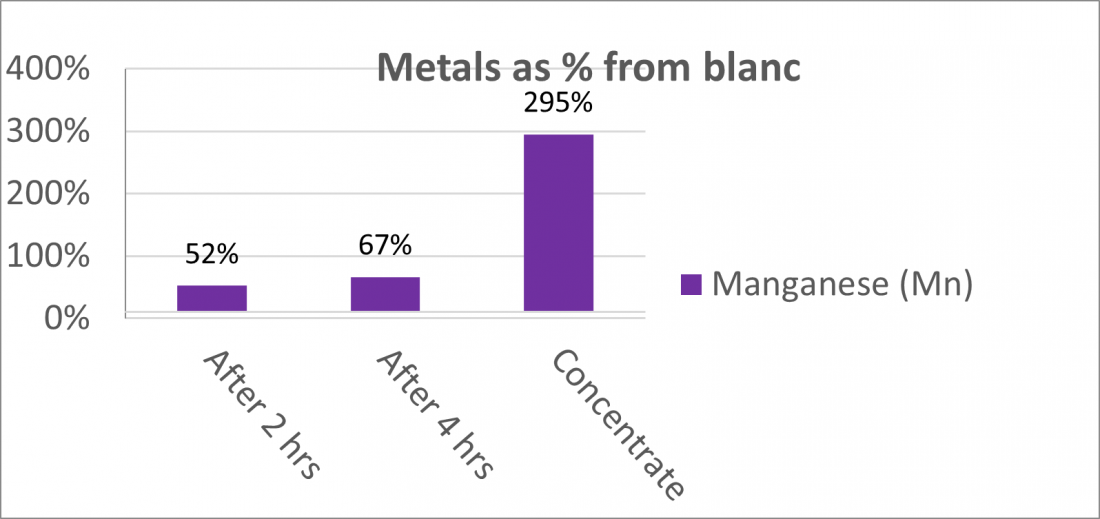

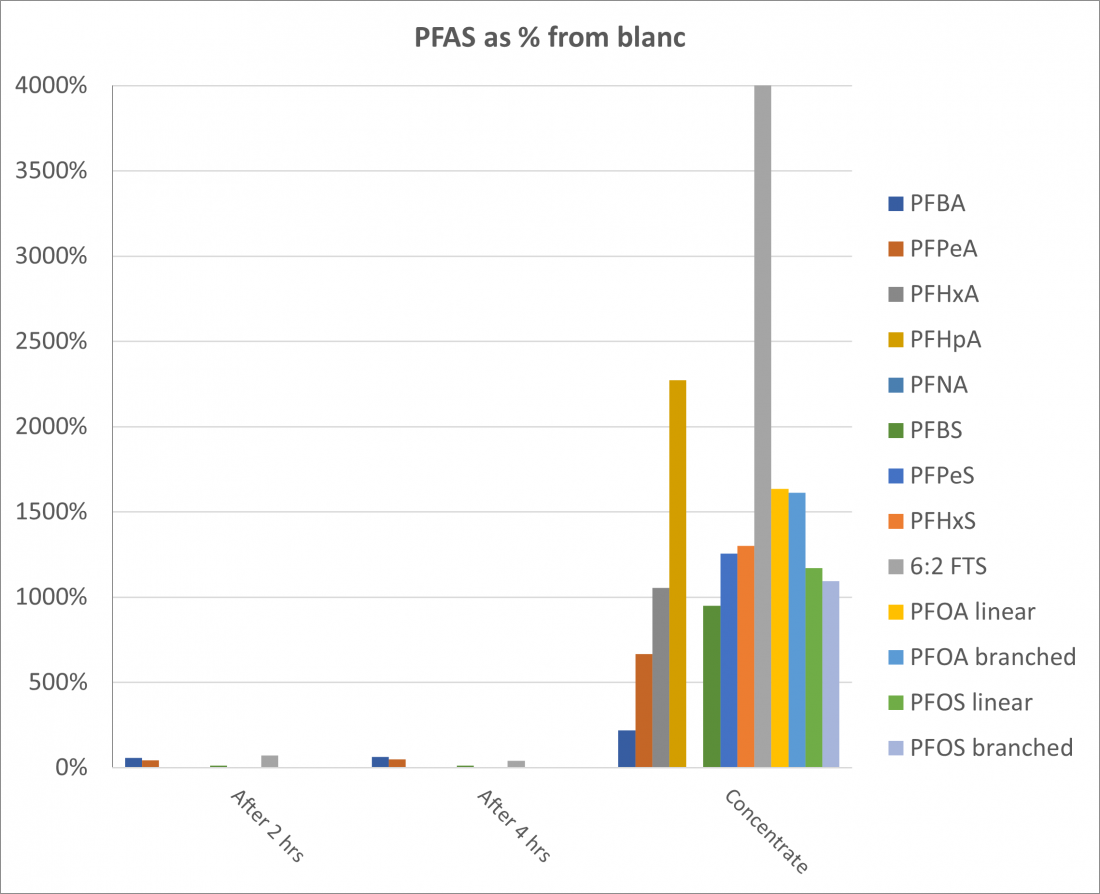

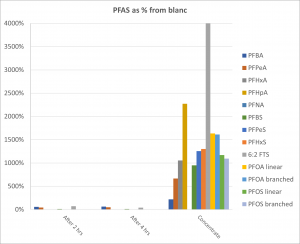

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

Benchtest ozofractionation on leachate

The project

In cooperation with KWR a bench test ozofractionation was executed on leachate water from a landfill (post MBR treatment). Ozofractionation is an innovative technology suitable for the treatment of waste waters that are also impacted with PFAS. The technology is based on the separation of PFAS from the wastewater by means of microbubbles of ozone. These microbubbles pick up the PFAS from the wastewater stream and generate a foam layer that can be separated from the water stream. Additional effect is that, due to the injection of the ozone, the degradable components in the wastewater (non-PFAS) are degraded and/or mineralized. Certain metals are converted into metal oxides that will also accumulate in the foam layer. Leachate water from landfills is known to have a high content of organic components (COD/BOD), (heavy) metals and salts. In the specific sample used for testing, the chloride content was 28 g/L. The manganese level was 21 mg/L. The total amount of PFAS was 26.4 µg/L with PFOA being the component most abundantly present.

Approach and results

At the laboratory of KWR in Nieuwegein (Th Netherlands) a bench scale ozofractionation system was set up. First preliminary beaker tests were performed to assess the intensity of the foam generation when using air or ozone. After the beaker tests the reactor was filled with the leachate and the tests were performed.

Almost immediately after the start of the ozofractionation test, a strong color change appeared. The colorless but turbid water sample turned purple, most likely due to the production of permanganate in this very oxidative environment. PFOS (linear and branched) and PFOA (branched) were completely removed from the wastewater. The removal efficacy for linear PFOA was 99,76%. The results of the foam concentrate clearly showed the accumulation of PFAS. For PFOA and PFOS this factor was a factor 10 to 16. The concentrations of barium, cadmium and lead were not influenced. The concentration of cobalt, cupper, iron, manganese, molybdenum, nickel and zinc are reduced in the wastewater and accumulate in the foam concentrate.

Project data

Location project: Laboratory of KWR, Nieuwegein, The Netherlands

Executed by: Arcadis, Evocra and KWR

Contact person: Wim Plaisier

-

- PFAS Cleaning Treatment Solutions

- PFAS Cleaning Treatment Solutions

-

- info@pfasoplossingen.nl

-

- Phone number

- +31(0)646647255